supply chain rfid barcode scanner To understand the advantages and disadvantages of RFID, let’s take a closer look at some situations where it’s a better choice than barcoding. RFID is available in three main . Tap the Automation tab. Tap the Plus (+) icon to create a new automation. Select Create Personal Automation. Scroll down and tap NFC as the automation trigger. Tap Scan. When you see the Ready to .

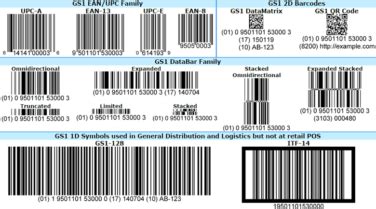

0 · supply chain barcodes

1 · rfid vs barcode supply chain

2 · rfid vs barcode scanner

3 · rfid vs barcode inventory

4 · rfid vs barcode

5 · rfid tags and scanners

6 · rfid supply chain management

7 · rfid scanner for warehouse

An attacker has hidden an NFC reader behind an NFC-based kiosk in an airport. The attacker uses the device to capture NFC data in transit b/w end user devices and the reader in the .

What is RFID in the supply chain? Radio frequency identification (RFID) is a type of wireless communication technology that uses a scanning antenna, a transceiver and a . To understand the advantages and disadvantages of RFID, let’s take a closer look at some situations where it’s a better choice than barcoding. RFID is available in three main .

rfid reader alibaba

Incorporating RFID vs barcode for your supply chain management is critical to enhances the accuracy of data capture, expedites identification, and facilitates smoother . What is RFID in the supply chain? Radio frequency identification (RFID) is a type of wireless communication technology that uses a scanning antenna, a transceiver and a transponder. An RFID reader is made up of the antenna and transceiver. The transponder is known as an RFID tag or smart label. To understand the advantages and disadvantages of RFID, let’s take a closer look at some situations where it’s a better choice than barcoding. RFID is available in three main types: low frequency (LF), high frequency (HF), and ultra-high frequency (UHF).

Incorporating RFID vs barcode for your supply chain management is critical to enhances the accuracy of data capture, expedites identification, and facilitates smoother operations throughout the supply chain.

rfid reader github

RFID tags and scanners can potentially improve product and materials handling inside and outside the warehouse environment, with applications ranging from inventory management to automation. Here are some of the benefits RFID can bring to the supply chain. 1. Improves product tracking through WMS integration. This comprehensive guide dives into the RFID vs barcode supply chain debate, analysing the pros and cons, costs, and real-world examples. In supply chain management, RFID (Radio-Frequency Identification) and barcodes are vital for tracking and managing inventory. An RFID tag ensures a manufacturer can track every single part it uses in its goods, providing visibility over every moving part in the supply chain. The wondrous world of RFID tech extends well beyond supply chain management. Putting RFID to use helps businesses easily locate specific items within warehouses, zero in on inventory trends, and maintain regulatory compliance. It provides detailed visibility into the supply chain, enabling automated reordering, and streamlined returns.

rfid reader and emulator

Shop Products Catalog. Contact Us. Our Proud Partnerships for Track and Trace Solutions. What We Offer. Enterprise Mobility. We provide mobile device deployment, management and service solutions for barcode and RFID scanners, rugged tablets, and mobile computers. Read More. IoT Asset Tracking.

Radio frequency identification (RFID) is a critical component of the modern supply chain. This wireless technology relies on radio waves to capture and convey essential information. Bar code labels can provide product identification similar to RFID tags, but scanners need a clear line of sight. RFID allows for bulk reading, streamlining key warehousing, and distribution steps. You can also use RFID tags to . What is RFID in the supply chain? Radio frequency identification (RFID) is a type of wireless communication technology that uses a scanning antenna, a transceiver and a transponder. An RFID reader is made up of the antenna and transceiver. The transponder is known as an RFID tag or smart label. To understand the advantages and disadvantages of RFID, let’s take a closer look at some situations where it’s a better choice than barcoding. RFID is available in three main types: low frequency (LF), high frequency (HF), and ultra-high frequency (UHF).

Incorporating RFID vs barcode for your supply chain management is critical to enhances the accuracy of data capture, expedites identification, and facilitates smoother operations throughout the supply chain.

RFID tags and scanners can potentially improve product and materials handling inside and outside the warehouse environment, with applications ranging from inventory management to automation. Here are some of the benefits RFID can bring to the supply chain. 1. Improves product tracking through WMS integration.

This comprehensive guide dives into the RFID vs barcode supply chain debate, analysing the pros and cons, costs, and real-world examples. In supply chain management, RFID (Radio-Frequency Identification) and barcodes are vital for tracking and managing inventory. An RFID tag ensures a manufacturer can track every single part it uses in its goods, providing visibility over every moving part in the supply chain. The wondrous world of RFID tech extends well beyond supply chain management.

supply chain barcodes

rfid vs barcode supply chain

Putting RFID to use helps businesses easily locate specific items within warehouses, zero in on inventory trends, and maintain regulatory compliance. It provides detailed visibility into the supply chain, enabling automated reordering, and streamlined returns.Shop Products Catalog. Contact Us. Our Proud Partnerships for Track and Trace Solutions. What We Offer. Enterprise Mobility. We provide mobile device deployment, management and service solutions for barcode and RFID scanners, rugged tablets, and mobile computers. Read More. IoT Asset Tracking.

Radio frequency identification (RFID) is a critical component of the modern supply chain. This wireless technology relies on radio waves to capture and convey essential information.

rfid vs barcode scanner

rfid reader specifications

rfid reader writer software mac

QUICK ANSWER. NFC tags and readers communicate wirelessly with each other .

supply chain rfid barcode scanner|rfid vs barcode inventory