your vendors will send the rfid tag data using The process of identifying an asset using RFID involves three main components – the tag itself, a reader or scanner device, and a database or software system for storing and managing data. The first step is encoding information on to each unique tag before attaching it to an asset. It means that your NFC (Near Field Communication) is turned on and your phone has come into contact with an NFC-enabled device or credit/debit card. If it is enabled, the NFC sensor will look for magnetic objects within its .

0 · what is rfid in supply chain

1 · rfid scanning in supply chain

2 · rfid inventory tracking

3 · rfid in logistics

4 · rfid examples in supply chain

5 · rfid examples in manufacturing

6 · examples of rfid tags

7 · examples of rfid inventory

Overview Specification Applications Support. ACR122U is a PC-linked contactless smart card reader/writer developed based on the 13.56 MHz Contactless (RFID) Technology. Compliant with the ISO/IEC18092 standard .If you want to use USB to connect to your reader / writer, I would go for the ACR122U. It works .

Easily reading data from RFID tags allows you to identify single items or entire batches of goods simultaneously. To help you understand every element involved, here’s what you need to know about storing and reading data on and from RFID tags.

The process of identifying an asset using RFID involves three main components – the tag itself, a reader or scanner device, and a database or software system for storing and managing data. The first step is encoding information on to each unique tag before attaching it to an asset. RFID tracking involves attaching an RFID tag loaded with data, including name, condition, amount, and location, to relevant assets. The RFID reader captures the stored data through pulsating. Retail companies use RFID to get information on inventory and to attempt to thwart thefts, among other uses. For example, RFID tags can help clothing store employees discover that a particular size of jeans is in stock, even though it's missing from the right shelf. Easily reading data from RFID tags allows you to identify single items or entire batches of goods simultaneously. To help you understand every element involved, here’s what you need to know about storing and reading data on and from RFID tags.

The process of identifying an asset using RFID involves three main components – the tag itself, a reader or scanner device, and a database or software system for storing and managing data. The first step is encoding information on to each unique tag before attaching it to an asset.

what is rfid in supply chain

rfid scanning in supply chain

RFID tracking involves attaching an RFID tag loaded with data, including name, condition, amount, and location, to relevant assets. The RFID reader captures the stored data through pulsating. Retail companies use RFID to get information on inventory and to attempt to thwart thefts, among other uses. For example, RFID tags can help clothing store employees discover that a particular size of jeans is in stock, even though it's missing from the right shelf. How to Store and Read RFID Tag Data. Every RFID solution comprises two main elements: the tags attached to items, and the readers that interrogate those tags. Tags use a chip to store information and can transmit that data via a . RFID asset tracking is a method of physically tracking assets using RFID technology (radio waves), which enables faster identification and inventory. In simple words, there’s an RFID tag attached to your asset and the RFID reader communicates with the tag from a distance, even without a line of sight, to confirm the existence of the asset.

RFID technology is used in inventory management to track and manage assets efficiently, accurately, and securely. RFID systems consist of two main parts: tags and readers. The tag stores a unique identifier and communicates data to the reader using radio waves. How RFID Works. When an RFID reader emits a signal, nearby RFID tags respond by sending their unique identification numbers back to the reader. The reader then passes this information to the middleware, which processes it, often displaying the asset's location on a . RFID tag testing must be done to ensure that the tag can be read easily on the product / product packaging. Test each RFID tag at different places, orientations, and angles, and use ARC’s Tagging Guidelines by Packaging Type as your guide.

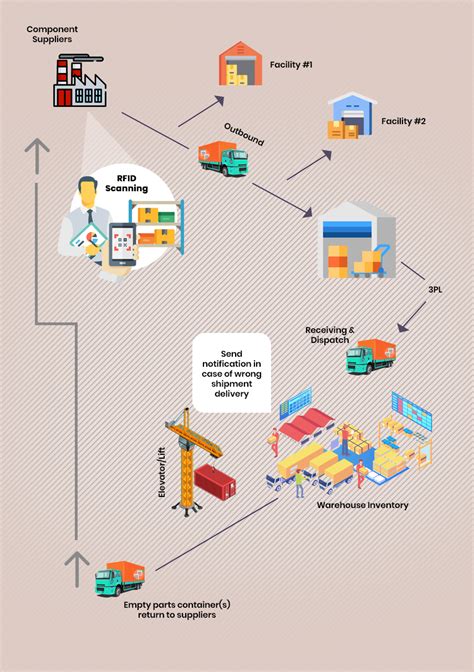

With the use of RFID tags on suppliers’ inventory, it is easy to know stock availability and its location. Shipment to customers will be faster. For the Consignment Inventory technique, the product ownership is with the vendor or supplier until the product is . Easily reading data from RFID tags allows you to identify single items or entire batches of goods simultaneously. To help you understand every element involved, here’s what you need to know about storing and reading data on and from RFID tags.

rfid inventory tracking

The process of identifying an asset using RFID involves three main components – the tag itself, a reader or scanner device, and a database or software system for storing and managing data. The first step is encoding information on to each unique tag before attaching it to an asset. RFID tracking involves attaching an RFID tag loaded with data, including name, condition, amount, and location, to relevant assets. The RFID reader captures the stored data through pulsating.

Retail companies use RFID to get information on inventory and to attempt to thwart thefts, among other uses. For example, RFID tags can help clothing store employees discover that a particular size of jeans is in stock, even though it's missing from the right shelf. How to Store and Read RFID Tag Data. Every RFID solution comprises two main elements: the tags attached to items, and the readers that interrogate those tags. Tags use a chip to store information and can transmit that data via a . RFID asset tracking is a method of physically tracking assets using RFID technology (radio waves), which enables faster identification and inventory. In simple words, there’s an RFID tag attached to your asset and the RFID reader communicates with the tag from a distance, even without a line of sight, to confirm the existence of the asset. RFID technology is used in inventory management to track and manage assets efficiently, accurately, and securely. RFID systems consist of two main parts: tags and readers. The tag stores a unique identifier and communicates data to the reader using radio waves.

upsrtc smart card recharge

How RFID Works. When an RFID reader emits a signal, nearby RFID tags respond by sending their unique identification numbers back to the reader. The reader then passes this information to the middleware, which processes it, often displaying the asset's location on a . RFID tag testing must be done to ensure that the tag can be read easily on the product / product packaging. Test each RFID tag at different places, orientations, and angles, and use ARC’s Tagging Guidelines by Packaging Type as your guide.

rfid in logistics

First things first, make sure your phone supports NFC, and ask for the permission nod in your AndroidManifest. Then, it's showtime – you've got two cool moves: reading and .I go to my current Activity and initialize the NFC Adapter onCreate: mNfcAdapter = NfcAdapter.getDefaultAdapter(this) What would be the next step to read the nfc tag NDEF .

your vendors will send the rfid tag data using|rfid examples in supply chain