rfid tags for inventory management RFID Tags. Used for stock control, RFID tags are integrated circuits that use a microchip attached to an antenna to transmit and receive data. With the ability to store a wide range of information and provide faster scanning, RFID tags can be active and passive. They work perfectly. A set of all 22 should cost you $10 - $20 depending on how pretty you .

0 · waverfid login

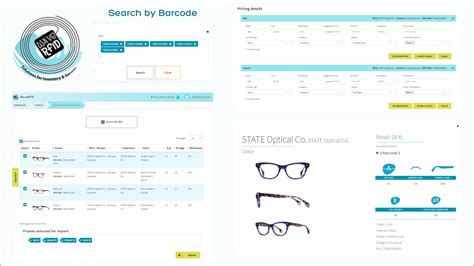

1 · warehouse rfid inventory management software

2 · using rfid to locate items

3 · rfid tags to track objects

4 · rfid scanner to locate items

5 · rfid in inventory management pdf

6 · rfid based warehouse management system

7 · rfid based inventory tracking system

I've set off store alarms maybe 4 or 5 times in 25 years. If it's a store you shop .The HID Prox system operates at a carrier frequency of 125 kHz. NFC operates at 13.56 MHz. Consequently, it's impossible to read HID Prox cards with an NFC reader. But if you will android HCE, the android device can act as HID tag which can we read by RFID reader. .

Learn how RFID technology can automate and improve your inventory tracking, accuracy, and efficiency. Compare RFID with barcodes, explore the pros and cons, and see real-life examples of RFID adoption in . Learn what RFID inventory management is, how it works, and its pros and cons. Compare RFID with barcode labels and find out how to choose the best inventory management software for your business. In RFID-empowered inventory management, each item gets an RFID tag. The tag stores all pertinent data. RFID readers, then, remotely fetch this data, adding up-to-the-minute precision to inventory counts. RFID Tags. Used for stock control, RFID tags are integrated circuits that use a microchip attached to an antenna to transmit and receive data. With the ability to store a wide range of information and provide faster scanning, RFID tags can be active and passive.

RFID Tags: These are small, electronic labels discreetly attached to your assets. They house a microchip for data storage and an antenna that transmits this information when activated. RFID Tags come in various shapes, sizes, and materials to suit diverse inventory needs.RFID tags for inventory management can be attached to products or pallets, which then automatically transmit information to RFID readers. This real-time capturing of product identity allows for inventory tracking that is more efficient, more .

Supply chain visibility. Inventory has never been done — before now! SimplyRFiD teaches you to accurately tag and track inventory in ways that have been dreamt about but never realized. Barcodes aren’t capable of accurate inventory, and new systems and techniques are required. In inventory management, UHF RFID tags track and manage inventory levels. They attach to items, pallets, or containers, and are read by RFID readers to collect data on the location, movement, and status of inventory items.Our advanced RFID tags and components optimize asset tracking and logistics systems by automating the delivery of actionable data of the precise location of key physical & human assets through passive RFID and/or active IoT technology. Learn how asset and inventory tracking can benefit the construction industry. Asset Tracking Systems.

Radio-frequency identification (RFID) is technology that uses electromagnetic fields to identify, track, and transmit data—such as the specific item number, batch number, or item production date—via a tag that is attached to an item. Manage inventory with RFID tags. RFID inventory systems are popular because they help retailers locate product information quickly, monitor inventory levels, and minimize shrinkage. If you’re unsure of whether you should be using RFID for inventory management, launch a pilot scheme.

RFID Technology Improves Efficiency: RFID tags enhance inventory management by allowing automated, real-time scanning, reducing manual labour and errors. Enhanced Visibility and Real-Time Tracking: RFID technology offers real-time tracking of assets, crucial for businesses with multiple locations or large warehouses. In RFID-empowered inventory management, each item gets an RFID tag. The tag stores all pertinent data. RFID readers, then, remotely fetch this data, adding up-to-the-minute precision to inventory counts. RFID Tags. Used for stock control, RFID tags are integrated circuits that use a microchip attached to an antenna to transmit and receive data. With the ability to store a wide range of information and provide faster scanning, RFID tags can be active and passive.

RFID Tags: These are small, electronic labels discreetly attached to your assets. They house a microchip for data storage and an antenna that transmits this information when activated. RFID Tags come in various shapes, sizes, and materials to suit diverse inventory needs.RFID tags for inventory management can be attached to products or pallets, which then automatically transmit information to RFID readers. This real-time capturing of product identity allows for inventory tracking that is more efficient, more .Supply chain visibility. Inventory has never been done — before now! SimplyRFiD teaches you to accurately tag and track inventory in ways that have been dreamt about but never realized. Barcodes aren’t capable of accurate inventory, and new systems and techniques are required.

In inventory management, UHF RFID tags track and manage inventory levels. They attach to items, pallets, or containers, and are read by RFID readers to collect data on the location, movement, and status of inventory items.Our advanced RFID tags and components optimize asset tracking and logistics systems by automating the delivery of actionable data of the precise location of key physical & human assets through passive RFID and/or active IoT technology. Learn how asset and inventory tracking can benefit the construction industry. Asset Tracking Systems. Radio-frequency identification (RFID) is technology that uses electromagnetic fields to identify, track, and transmit data—such as the specific item number, batch number, or item production date—via a tag that is attached to an item. Manage inventory with RFID tags. RFID inventory systems are popular because they help retailers locate product information quickly, monitor inventory levels, and minimize shrinkage. If you’re unsure of whether you should be using RFID for inventory management, launch a pilot scheme.

waverfid login

rfid icon on credit card

rfid hotel cards

2- Preparing to Program Your NFC Tag. 3- Step by Step Directions to Program Your NFC Tag. 3.1- Step 1: Setting Up Your NFC-Enabled Device. 3.2- Step 2: Selecting the Content for Your NFC Tag. 3.3- Step 3: Writing the .

rfid tags for inventory management|using rfid to locate items