warehouse management system rfid RFID Warehouse Management is a great way to improve overall efficiency. To learn about the pros & cons - Click Here! If you’ve wondered whether or not RFID tagging is right for asset management in your warehouse, we’ve got answers for you.

Complete These Steps: Ensure your console has the latest system update. Start the amiibo-compatible game and follow the on-screen instructions. Note: You may need to look up the software manual .

0 · using rfid to track inventory

1 · rfid warehouse tracking system

2 · rfid warehouse management system requirements

3 · rfid warehouse inventory management

4 · rfid tracking systems for inventory

5 · rfid in warehouse management pdf

6 · rfid disadvantages

7 · pros and cons of rfid

NFC-V is a type that has an 8 byte UID length while other NFC types usually only have a UID length of 7 bytes. As of now, Flipper only supports 7 byte versions. I‘ve read somewhere on their Discord, however, that NFC-V support is .

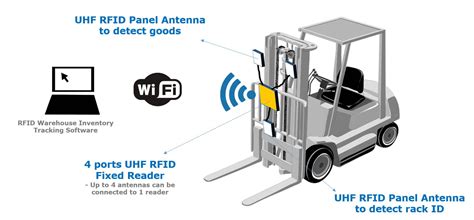

Learn how RFID tags and systems can improve warehouse efficiency, accuracy and speed. Prologis offers insights and solutions to optimize your warehouse with RFID. What is RFID in Your Warehouse Management System? Radio Frequency Identification (RFID) is a cutting-edge technology that uses radio waves to automatically .With an RFID warehouse management tracking system, items can be scanned and catalogued from anywhere, even when they’re hidden behind boxes or pallets. RFID tags can also be detected and read remotely and simultaneously. What is RFID in Your Warehouse Management System? Radio Frequency Identification (RFID) is a cutting-edge technology that uses radio waves to automatically identify and track tags attached to objects.

The implementation of RFID technology revolutionizes the real-time tracking and visibility of inventory within a warehouse. With RFID, tagged items can be monitored constantly, providing up-to-the-minute location data, which in turn significantly reduces the likelihood of lost or misplaced goods.

RFID Warehouse Management is a great way to improve overall efficiency. To learn about the pros & cons - Click Here! If you’ve wondered whether or not RFID tagging is right for asset management in your warehouse, we’ve got answers for you. What is RFID System in warehousing? With RFID warehouse management software, items can be scanned and cataloged from anywhere, even hidden in boxes or pallets. RFID tags can even be detected and read remotely and simultaneously.

By utilizing RFID technology, warehouses can achieve higher inventory accuracy, faster cycle counts, reduced labor costs, improved order fulfillment, and better overall supply chain visibility. RFID systems operate on different frequency bands depending on . Discover how implementing an RFID warehouse management system can improve operational efficiency and get the most out of your warehouse. Learn about the benefits, tips for successful implementation, and if it is right for you.

using rfid to track inventory

RFID is changing the game in warehouse management. But what is RFID? RFID stands for Radio Frequency Identification. It’s a technology that uses radio waves to track and identify items, providing unique identification and efficiency. Think of . What Is RFID Warehouse Management? RFID, or Radio-Frequency Identification, is commonly used in warehouse management and logistics to track and manage inventory and assets more efficiently. It relies on radio waves to transmit data between an . Discover how to optimize warehouse operations with RFID technology in this comprehensive guide to RFID warehouse management. RFID (Radio Frequency Identification) technology has revolutionized the way warehouses manage their .

With an RFID warehouse management tracking system, items can be scanned and catalogued from anywhere, even when they’re hidden behind boxes or pallets. RFID tags can also be detected and read remotely and simultaneously.

What is RFID in Your Warehouse Management System? Radio Frequency Identification (RFID) is a cutting-edge technology that uses radio waves to automatically identify and track tags attached to objects.

The implementation of RFID technology revolutionizes the real-time tracking and visibility of inventory within a warehouse. With RFID, tagged items can be monitored constantly, providing up-to-the-minute location data, which in turn significantly reduces the likelihood of lost or misplaced goods. RFID Warehouse Management is a great way to improve overall efficiency. To learn about the pros & cons - Click Here! If you’ve wondered whether or not RFID tagging is right for asset management in your warehouse, we’ve got answers for you. What is RFID System in warehousing? With RFID warehouse management software, items can be scanned and cataloged from anywhere, even hidden in boxes or pallets. RFID tags can even be detected and read remotely and simultaneously. By utilizing RFID technology, warehouses can achieve higher inventory accuracy, faster cycle counts, reduced labor costs, improved order fulfillment, and better overall supply chain visibility. RFID systems operate on different frequency bands depending on .

Discover how implementing an RFID warehouse management system can improve operational efficiency and get the most out of your warehouse. Learn about the benefits, tips for successful implementation, and if it is right for you. RFID is changing the game in warehouse management. But what is RFID? RFID stands for Radio Frequency Identification. It’s a technology that uses radio waves to track and identify items, providing unique identification and efficiency. Think of . What Is RFID Warehouse Management? RFID, or Radio-Frequency Identification, is commonly used in warehouse management and logistics to track and manage inventory and assets more efficiently. It relies on radio waves to transmit data between an .

smart card reader circuit diagram

smart card reader access is denied

The Nintendo 3DS NFC Reader/Writer is an attachment for the Nintendo 3DS, Nintendo 3DS .

warehouse management system rfid|rfid warehouse management system requirements