production problems solved by rfid system Discover the most common RFID problems and learn proven solutions to optimize your system’s performance. This comprehensive guide covers troubleshooting tips for signal interference, power supply, tag placement, and more. With foldable arm, small size, easy to carry. GPS positioning mode provides a more .

0 · rfid pdf download

1 · rfid not working

2 · rfid interference

3 · rfid industry trends

4 · rfid industry issues

5 · rfid disadvantages

6 · rfid book pdf

7 · cons of rfid

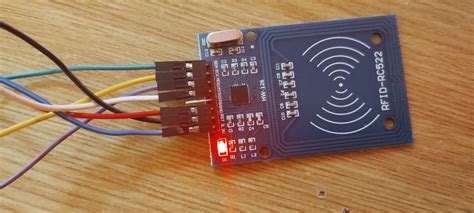

Re: PN532 NFC/RFID reading multiple tags. by jarkesia » Sat Jun 29, 2013 4:18 pm. If you are using Mifare tags PN532 API has a command to call for known tags. So if you .

Discover the most common RFID problems and learn proven solutions to optimize your system’s performance. This comprehensive guide covers troubleshooting tips for signal interference, power supply, tag placement, and more. The benefits of implementing RFID technologies can be seen in terms of efficiency (increased speed in production, reduced shrinkage, lower .

Discover the most common RFID problems and learn proven solutions to optimize your system’s performance. This comprehensive guide covers troubleshooting tips for signal interference, power supply, tag placement, and more. The benefits of implementing RFID technologies can be seen in terms of efficiency (increased speed in production, reduced shrinkage, lower error rates, improved asset tracking etc.) or effectiveness (services that companies provide to the customers). There are some important trends—and some issues—facing the industry. Key Takeaways. The RFID industry is growing fast and will continue to grow over the next five years. UHF tags are the fastest-growing segment, while logistics and supply chain management is the fastest-growing application.The major challenge is the price and return on investment (ROI) in the implementation of RFID technology. Companies have to bear the cost of all RFID elements; RFID tags, readers, hardware, software along with the routine maintenance.

When we are referring to RFID in manufacturing we are talking about the use of radio signals to help various areas, from supply chain to inventory management, to production. RFID tags can store a broad assortment of data that can be used in several ways within manufacturing and can help streamline and optimise the whole production process.

Although the number of firms adopting RFID technology is continuously increasing, there are still some unresolved issues with RFID systems such as concerns of data reliability, security, privacy, and justification of return on investment.

RFID can address numerous manufacturing challenges, including security, quality control, production execution and asset management. When implementing the technology in a manufacturing environment, however, the key is not the tag, the reader or the part identification. Rather, it is the data that can be obtained. A range of problems unique to fashion industry can be solved by installing the RFID system in various processes involved in fashion supply chain. Fashion industry can be divided into four sectors such as manufacturing, overseas transportation, distribution and retailing. The review covered various themes, including organizational strategies towards adopting new technologies, including RFID, sustainable development, modern techniques, information system approaches towards supply chain designing and their management, and benefits of RFID and Industry 4.0.

Many RFID applications are close-loop scenarios devised to solve particular problems in industry when alternative solutions are not feasible. RFID tools have assumed an important role in supporting assembly lines, logistics, and supply chain management processes.Discover the most common RFID problems and learn proven solutions to optimize your system’s performance. This comprehensive guide covers troubleshooting tips for signal interference, power supply, tag placement, and more.

The benefits of implementing RFID technologies can be seen in terms of efficiency (increased speed in production, reduced shrinkage, lower error rates, improved asset tracking etc.) or effectiveness (services that companies provide to the customers).

There are some important trends—and some issues—facing the industry. Key Takeaways. The RFID industry is growing fast and will continue to grow over the next five years. UHF tags are the fastest-growing segment, while logistics and supply chain management is the fastest-growing application.The major challenge is the price and return on investment (ROI) in the implementation of RFID technology. Companies have to bear the cost of all RFID elements; RFID tags, readers, hardware, software along with the routine maintenance.

When we are referring to RFID in manufacturing we are talking about the use of radio signals to help various areas, from supply chain to inventory management, to production. RFID tags can store a broad assortment of data that can be used in several ways within manufacturing and can help streamline and optimise the whole production process. Although the number of firms adopting RFID technology is continuously increasing, there are still some unresolved issues with RFID systems such as concerns of data reliability, security, privacy, and justification of return on investment.

RFID can address numerous manufacturing challenges, including security, quality control, production execution and asset management. When implementing the technology in a manufacturing environment, however, the key is not the tag, the reader or the part identification. Rather, it is the data that can be obtained. A range of problems unique to fashion industry can be solved by installing the RFID system in various processes involved in fashion supply chain. Fashion industry can be divided into four sectors such as manufacturing, overseas transportation, distribution and retailing.

rfid pdf download

The review covered various themes, including organizational strategies towards adopting new technologies, including RFID, sustainable development, modern techniques, information system approaches towards supply chain designing and their management, and benefits of RFID and Industry 4.0.

chip rfid pasaporte

covid 19 vaccine rfid chips

In order to read NFC tags, you need to create an instance of the NFC adapter class. This can be done using the getSystemService() method. Add the following code to your Activity’s onCreate() method.

production problems solved by rfid system|rfid industry trends