rfid dry inlay Learn about dry RFID inlays, the best applications for them, and how transfer tape and gum . At the same time, web links, phone numbers, entire contacts, texts and locations can be written to and read from an NFC tag. If the NFC function has been activated on the Android smartphone (Activate NFC on Android), the .

0 · wet rfid vs dry inlay

1 · rfid vs wet inlays

2 · rfid tags for zebra printers

3 · rfid lost freight labels 4x6

4 · rfid labels for zebra printers

5 · rfid inlays means

6 · rfid inlay manufacturers

7 · rfid catalog

Put the NFC card on the portal. Click on 'Portal' and then on 'Read Figure' or 'Read Skylander from portal' If your figure shows up it works and optional you can edit gold level and skill path .

Learn about dry RFID inlays, the best applications for them, and how transfer tape and gum .

RFID and digital ID. atma.io. Industries. Automotive. Appliances & industrial. .We would like to show you a description here but the site won’t allow us.Albania, Croatia, Czechia (Czech Republic), Estonia, Hungary, Latvia, Lithuania, .It’s time to think about products in a new way, beyond the point of use. We’re .

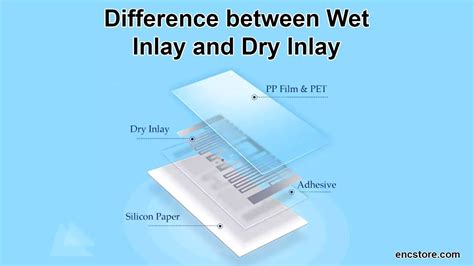

In the wide application of RFID technology, wet inlay and dry inlay are two common forms of tags, each with its advantages. This article will comprehensively compare the two inlays and explore the differences in their manufacturing .

Wet RFID inlays may be more suitable for applications where exposure to moisture or humidity is a concern due to their immediate adhesion properties. Dry RFID inlays might be preferred for applications where precise .Learn about dry RFID inlays, the best applications for them, and how transfer tape and gum twins ensure dry inlays will stick to what you’re tagging.

example of nfc tag

wet rfid vs dry inlay

In the wide application of RFID technology, wet inlay and dry inlay are two common forms of tags, each with its advantages. This article will comprehensively compare the two inlays and explore the differences in their manufacturing materials, durability, cost, and applicable environment. Wet RFID inlays may be more suitable for applications where exposure to moisture or humidity is a concern due to their immediate adhesion properties. Dry RFID inlays might be preferred for applications where precise placement or embedding within specific materials is necessary.` Wet versus dry — Adhesive-backed inlays are most common and can be used when no ancillary operations are required. These “wet” inlays typically come in rolls and can be quickly peeled off and adhered to the product. A wet inlay is delivered to the converter attached to a .Avery Dennison is committed to supporting converters and their customers worldwide through the RFID adoption process as they explore new opportunities in lab.

RAIN RFID inlays, tags and labels work in the Ultra-High Frequency Band and can provide a read range of up to 10 meters or 30 feet. This makes RAIN RFID systems ideal for many tracking applications.An RFID dry inlay is essentially an RFID chip and antenna laminated onto a substrate. Unlike wet inlays, dry inlays do not have an adhesive layer. This makes them highly versatile and customizable, suitable for integration into various end products.

Dry Inlays – a polyethylene terephthalate (PET) substrate with an RFID chip and antenna bonded to it and then sandwiched with another protective PET lamination layer and delivered in roll form. Wet Inlays – a Pressure Sensitive Inlays – same as Dry Inlay above, with the addition of a “wet” adhesive backing and liner. Dry RFID inlays involve a different process where the RFID chip and antenna are first assembled onto a carrier substrate, and then a dry adhesive layer is applied over them. In terms of functionality and application, there isn't typically a significant difference between wet and dry RFID inlays.

AD Squarewave inlays and tags are a size-optimized 97 mm / 4 inch form factor, making them suitable for use with a wide range of supply chain labels, and are available in dry, wet and label delivery formats.Learn about dry RFID inlays, the best applications for them, and how transfer tape and gum twins ensure dry inlays will stick to what you’re tagging.

In the wide application of RFID technology, wet inlay and dry inlay are two common forms of tags, each with its advantages. This article will comprehensively compare the two inlays and explore the differences in their manufacturing materials, durability, cost, and applicable environment. Wet RFID inlays may be more suitable for applications where exposure to moisture or humidity is a concern due to their immediate adhesion properties. Dry RFID inlays might be preferred for applications where precise placement or embedding within specific materials is necessary.` Wet versus dry — Adhesive-backed inlays are most common and can be used when no ancillary operations are required. These “wet” inlays typically come in rolls and can be quickly peeled off and adhered to the product. A wet inlay is delivered to the converter attached to a .

Avery Dennison is committed to supporting converters and their customers worldwide through the RFID adoption process as they explore new opportunities in lab.RAIN RFID inlays, tags and labels work in the Ultra-High Frequency Band and can provide a read range of up to 10 meters or 30 feet. This makes RAIN RFID systems ideal for many tracking applications.An RFID dry inlay is essentially an RFID chip and antenna laminated onto a substrate. Unlike wet inlays, dry inlays do not have an adhesive layer. This makes them highly versatile and customizable, suitable for integration into various end products. Dry Inlays – a polyethylene terephthalate (PET) substrate with an RFID chip and antenna bonded to it and then sandwiched with another protective PET lamination layer and delivered in roll form. Wet Inlays – a Pressure Sensitive Inlays – same as Dry Inlay above, with the addition of a “wet” adhesive backing and liner.

Dry RFID inlays involve a different process where the RFID chip and antenna are first assembled onto a carrier substrate, and then a dry adhesive layer is applied over them. In terms of functionality and application, there isn't typically a significant difference between wet and dry RFID inlays.

homeseer nfc tags

rfid vs wet inlays

hard-reset nfc tag

rfid tags for zebra printers

It will read just fine and show the notification without the need of opening tag reader. iPhones XS and up try to read NFC tags in the background all the time. Therefore manual reading was never an option to begin with. That is, if the .

rfid dry inlay|rfid inlay manufacturers