rfid saw tag In a delay line (DL) configuration, an ID code can be added in the time domain signal, hence the name SAW-RFID or SAW-Tag. In this communication, we showcase recent original examples of SAW RFID sensors for harsh environment temperature and strain sensing, based on innovative electrodes and substrates. Using NFC on Your IPhone. Hold the NFC tag near your iPhone to read it automatically. If you have an older iPhone, open the Control Center and tap the NFC icon. Move the tag over your phone to activate it. The NFC can .

0 · saw rfid

1 · rfid sensor

2 · global saw tag rfid

Step 1. Go to Settings > Connections > NFC and contactless payments. Step 2. Tap Contactless payments, and then select your preferred payment app. * Image shown is for illustration purposes only. Step 3. Additional payment apps can .Posted on Nov 1, 2021 12:10 PM. On your iPhone, open the Shortcuts app. Tap on the Automation tab at the bottom of your screen. Tap on Create Personal Automation. Scroll down and select NFC. Tap on Scan. Put your iPhone near the NFC tag. Enter a name for your tag. .

In a delay line (DL) configuration, an ID code can be added in the time domain signal, hence the name SAW-RFID or SAW-Tag. In this communication, we showcase recent .A key feature of SAW RFID tags is that they do not use any DC power source. SAW tags are truly passive devices that operate at any signal level (even very low) as long as the reply signal .RF SAW’s RFID system of interchangeable SAW tags, readers and antennae allow flexible systems to be customized for a wide range of industrial, military and commercial applications, . This chapter gives an overview of SAW based RFID transponders made for extreme conditions like temperatures up to 400°C or cryogenic temperatures down to –196°C. .

In a delay line (DL) configuration, an ID code can be added in the time domain signal, hence the name SAW-RFID or SAW-Tag. In this communication, we showcase recent original examples of SAW RFID sensors for harsh environment temperature and strain sensing, based on innovative electrodes and substrates.A key feature of SAW RFID tags is that they do not use any DC power source. SAW tags are truly passive devices that operate at any signal level (even very low) as long as the reply signal received at the reader is sufficient to detect the data.RF SAW’s RFID system of interchangeable SAW tags, readers and antennae allow flexible systems to be customized for a wide range of industrial, military and commercial applications, essentially providing a single worldwide solution for supply chain applications.

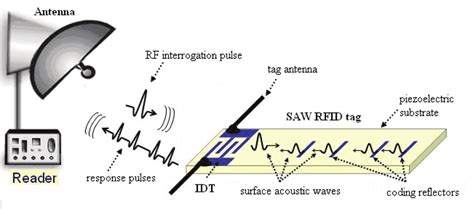

This chapter gives an overview of SAW based RFID transponders made for extreme conditions like temperatures up to 400°C or cryogenic temperatures down to –196°C. Their function principle and system performance is .RFSAW is exploiting a fundamentally new type of RFID system based on Surface Acoustic Wave (“SAW”) devices, a reliable, low-cost, well established RF wireless technology. The Company has invented, patented and successfully developed this new system whose core element is the “Global SAW Tag”. Acoustic Chipless RFID Sensors: SAW Tags A surface acoustic wave (SAW) tag [ 64 ] is comprised of a piezoelectric substrate, an inter-digital transducer (IDT), some metal reflectors, and antennas. When the RF reader interrogates the tag, the tag antenna collects the EM probing wave.

saw rfid

Design and operation of a typical SAW RFID tag. The principle benefit of this approach is that SAW RFID tags are capable of operating at much lower interrogator transmit power, and/or are capable of much greater range for a given transmit power than IC-based tags [Hartmann, et al.]. In this paper we discuss state-of-the-art in development of SAW-tags. The design approaches will be reviewed - and the most optimal tag designs are demonstrated, as well as encoding methods. We discuss the ways to reduce size and cost of these devices.The type of RFID tag introduced in this chapter, the surface acoustic wave (SAW) tag, is in many aspects similar to RF SAW filters, that are widely used in mobile phones.

Identification and localization of multiple SAW RFID tags are addressed in this work under this challenging effect, known as collision, with a multi-antenna mobile robot-based synthetic aperture approach. In a delay line (DL) configuration, an ID code can be added in the time domain signal, hence the name SAW-RFID or SAW-Tag. In this communication, we showcase recent original examples of SAW RFID sensors for harsh environment temperature and strain sensing, based on innovative electrodes and substrates.

card uid rfid

A key feature of SAW RFID tags is that they do not use any DC power source. SAW tags are truly passive devices that operate at any signal level (even very low) as long as the reply signal received at the reader is sufficient to detect the data.RF SAW’s RFID system of interchangeable SAW tags, readers and antennae allow flexible systems to be customized for a wide range of industrial, military and commercial applications, essentially providing a single worldwide solution for supply chain applications. This chapter gives an overview of SAW based RFID transponders made for extreme conditions like temperatures up to 400°C or cryogenic temperatures down to –196°C. Their function principle and system performance is .RFSAW is exploiting a fundamentally new type of RFID system based on Surface Acoustic Wave (“SAW”) devices, a reliable, low-cost, well established RF wireless technology. The Company has invented, patented and successfully developed this new system whose core element is the “Global SAW Tag”.

Acoustic Chipless RFID Sensors: SAW Tags A surface acoustic wave (SAW) tag [ 64 ] is comprised of a piezoelectric substrate, an inter-digital transducer (IDT), some metal reflectors, and antennas. When the RF reader interrogates the tag, the tag antenna collects the EM probing wave.Design and operation of a typical SAW RFID tag. The principle benefit of this approach is that SAW RFID tags are capable of operating at much lower interrogator transmit power, and/or are capable of much greater range for a given transmit power than IC-based tags [Hartmann, et al.]. In this paper we discuss state-of-the-art in development of SAW-tags. The design approaches will be reviewed - and the most optimal tag designs are demonstrated, as well as encoding methods. We discuss the ways to reduce size and cost of these devices.

The type of RFID tag introduced in this chapter, the surface acoustic wave (SAW) tag, is in many aspects similar to RF SAW filters, that are widely used in mobile phones.

rfid sensor

cf rfid card

card blocr credit card wallet slim rfid

$29.99

rfid saw tag|global saw tag rfid