encoder for rfid wet inlay INLAY POSITION WITHIN THE LABEL. The RFID tag must be positioned so it aligns correctly with the encoder antenna so that it can be read or written to. This positioning changes from . Start the amiibo-compatible game and follow the on-screen instructions. Please note that you may need to look up the software manual for information on where in the game you can use amiibo. .

0 · what is rfid inlay

1 · wet inlay vs rfid

2 · rfid tags and inlays

3 · rfid label encoder

4 · rfid inlay labels

5 · rfid encoder

6 · rfid antenna inlay

7 · pet rfid inlay

Get NFC Reader and Writer old version APK for Android. Download. About NFC .

china rfid key fob

what is rfid inlay

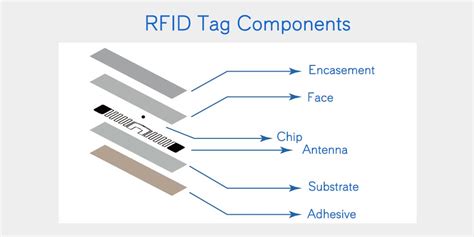

RFID Printers Encoders are used in applications where wet inlays or label are used to tag inventory or assets. The printers encoders not only print on the top of the label but also encode information into the RFID chip.INLAY POSITION WITHIN THE LABEL. The RFID tag must be positioned so it aligns correctly with the encoder antenna so that it can be read or written to. This positioning changes from . Avery Dennison - RFID WET inlays converting process. Avery Dennison is committed to supporting converters and their customers worldwide through the RFID adoption process as they explore new.

wet inlay vs rfid

RFID Printers Encoders are used in applications where wet inlays or label are used to tag inventory or assets. The printers encoders not only print on the top of the label but also encode information into the RFID chip.

INLAY POSITION WITHIN THE LABEL. The RFID tag must be positioned so it aligns correctly with the encoder antenna so that it can be read or written to. This positioning changes from one printer to the next, as many printers have their antennas placed at . Wet Inlays – a Pressure Sensitive Inlays – same as Dry Inlay above, with the addition of a “wet” adhesive backing and liner. Encapsulated or Durable Finished Transponders – an inlay with the addition of a durable encapsulate for longer tag life.

` Wet versus dry — Adhesive-backed inlays are most common and can be used when no ancillary operations are required. These “wet” inlays typically come in rolls and can be quickly peeled off and adhered to the product. A wet inlay is delivered to the converter attached to a .Delve into the technical aspects of RFID Dry Inlays and RFID Wet Inlays. Understand their specifications, applications, and key differences to make an informed choice for your RFID solution.

Wet inlay, due to its convenient usage and excellent performance, has become a preferred RFID solution for many enterprises. This article uses the Alien Higgs®EC UHF RFID Wet Inlay as an example to help users better understand how to use RFID wet inlay and some key considerations.Wet inlays and RFID labels can be run through an RFID printer for encoding and printing purposes. The specifications relating to media size and roll size are imperative to take into consideration when purchasing a printer, as well as when purchasing tags for that printer. Printing and encoding data on RFID inlays or labels simultaneously are done by RFID printers. The only method to print on labels is with one of these machines, and they also save time by automating the labor-intensive process of manually encoding each tag. Wet RFID inlays may be more suitable for applications where exposure to moisture or humidity is a concern due to their immediate adhesion properties. Dry RFID inlays might be preferred for applications where precise placement or embedding within specific materials is necessary.

Avery Dennison - RFID WET inlays converting process. Avery Dennison is committed to supporting converters and their customers worldwide through the RFID adoption process as they explore new. RFID Printers Encoders are used in applications where wet inlays or label are used to tag inventory or assets. The printers encoders not only print on the top of the label but also encode information into the RFID chip.INLAY POSITION WITHIN THE LABEL. The RFID tag must be positioned so it aligns correctly with the encoder antenna so that it can be read or written to. This positioning changes from one printer to the next, as many printers have their antennas placed at . Wet Inlays – a Pressure Sensitive Inlays – same as Dry Inlay above, with the addition of a “wet” adhesive backing and liner. Encapsulated or Durable Finished Transponders – an inlay with the addition of a durable encapsulate for longer tag life.

` Wet versus dry — Adhesive-backed inlays are most common and can be used when no ancillary operations are required. These “wet” inlays typically come in rolls and can be quickly peeled off and adhered to the product. A wet inlay is delivered to the converter attached to a .Delve into the technical aspects of RFID Dry Inlays and RFID Wet Inlays. Understand their specifications, applications, and key differences to make an informed choice for your RFID solution.Wet inlay, due to its convenient usage and excellent performance, has become a preferred RFID solution for many enterprises. This article uses the Alien Higgs®EC UHF RFID Wet Inlay as an example to help users better understand how to use RFID wet inlay and some key considerations.Wet inlays and RFID labels can be run through an RFID printer for encoding and printing purposes. The specifications relating to media size and roll size are imperative to take into consideration when purchasing a printer, as well as when purchasing tags for that printer.

Printing and encoding data on RFID inlays or labels simultaneously are done by RFID printers. The only method to print on labels is with one of these machines, and they also save time by automating the labor-intensive process of manually encoding each tag.

rfid tags and inlays

rfid label encoder

china sick rfid tag

china rfid tags

Stand alone NFC readers – Parking / TVM / TOM office points, Kiosks etc. Modules. DUAL antenna support ( e-toll / highway and road access) Water .

encoder for rfid wet inlay|wet inlay vs rfid